Precursors: the products that will eat away at the CBAM’s effectiveness

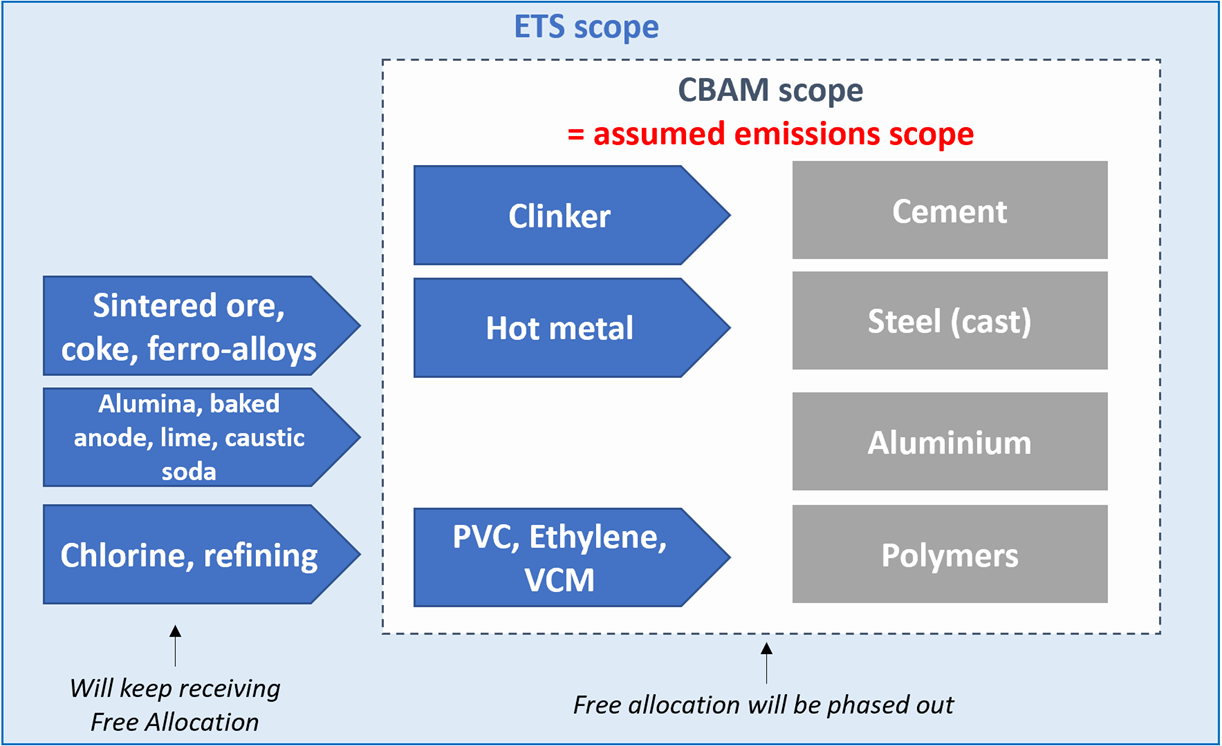

The proposed Cross-Border Adjustment Mechanism (CBAM) will charge a fee based on the carbon content of some industrial products imported into the EU (listed in Annex I of the regulation), but that may not be applicable to all the embedded emissions of these products. However, it should be noted that this fee may not cover all the embedded emissions associated with these products, particularly those related to the production of “complex” goods, as the plants producing their upstream components will continue to receive free allowances under the EU ETS.

Under legislative proposals from the European Commission, Parliament and Council, free allocation of emission allowances to EU plants will be phased out as the CBAM is phased in. However, in order to comply with WTO rules, the embedded emissions of “complex” imported goods cannot fully be covered by the CBAM because plants producing upstream products in the EU will keep receiving free emission allowances.

The European Commission is empowered, under Article 7(6) of the CBAM regulation, to define system boundaries for production processes by implementing acts, in order to determine which input materials are relevant for each good. However, this article will not be applicable to precursors that are not listed in Annex I of the same regulation, and which will keep on receiving free allowances under the EU ETS.

Steel

Take the example of steel products, which are set to be covered by the CBAM. Their production often involves various transformations using intermediate products (called ‘precursors’ under the regulation): coke, sintered ore and ferro-alloys. EU plants producing coke, sintered ore and ferro-alloys receive free allowances under the EU ETS and will continue to do so under all reform proposals[1].

For obvious WTO-compliance reasons, emissions from these precursors cannot be included in the CBAM charge covering imported steel products: allocating free permits to EU plants while levying the same imported goods with a carbon tax would create an unfair competitive advantage for EU goods.

According to the Commission[2], annual CO2 emissions from EU blast furnaces were 128.9 million tonnes in 2016/17. Another 23.2 million tonnes were emitted to produce sintered ore, 10.2 million to produce coke, and an undisclosed amount to produce ferro-alloys. Keeping these last three products out of the CBAM scope has a very significant impact on emissions estimates for steel products.

Aluminium

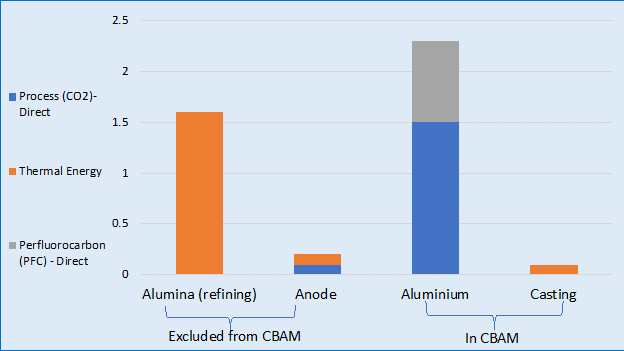

Precursors will also undermine the CBAM for aluminium imports. Aluminium’s precursors include alumina and baked anode, the production of which is eligible for free emission allowances under the ETS, so these products will have to stay outside the CBAM scope of aluminium emissions.

According to IAI figures, precursors emissions amount to nearly half of aluminium’s direct emissions on average globally.

Direct emissions (tonnes of CO2e per tonne of primary aluminium). Source: Greenhouse Gas Emissions Intensity- Primary Aluminium, International Aluminium (2022)

CBAM’s effectiveness diminished

Keeping precursors out of the CBAM is a policy error with grave consequences. It will reduce both the CBAM’s impact on imported carbon-intensive goods and the carbon costs borne by the most polluting EU-based plants, thereby keeping low-carbon products at a competitive disadvantage. In the steel sector, for example, this will perpetuate the huge disadvantage for the EAF steel production route, a process that can be fed on up to 100% scrap and has a high abatement potential as explained in Sandbag’s report here.

Steel and aluminium are only two examples. The exclusion of precursors from Annex I of the CBAM regulation also affects other sectors.

Our recommendations

- A faster phase-in of the CBAM and phase-out of free allocation of emission allowances under the ETS.

- In the CBAM regulation, include provisions allowing the phasing out of free allocation for any precursors of goods listed in Annex I.

- The above provisions should allow for the quick addition of new precursors, as value chains may adapt to changing regulation.