Report | Starting from scrap

The key role of circular steel in achieving climate goals.

This report aims at highlighting the role circularity can have in the fast decarbonization of the steel sector. How can European industrial and climate policy accelerate this transition?

Summary

- 97% of the EU’s direct emissions from the steel industry come from integrated steelmaking (BF-BOF route) used for higher quality products, while electric arc furnaces (EAF) tend to produce long and specialty steel products. However, in North America EAFs are more commonly used for flat products as well.

- 74% of blast furnace capacity will have to be relined (renovated) this decade.

- BF-BOF steel mills typically use 20% scrap (which reduces their carbon footprint) but the technology does not allow to use significantly more.

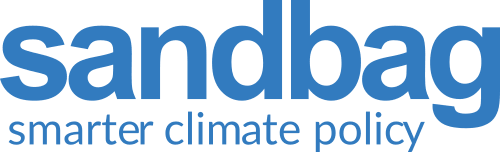

- All those BF-BOF steel mills could be replaced with EAFs fed by the same proportion (20%) of scrap, achieving 55% emission reductions by 2030, but that would increase annual fossil gas consumption (in 2030) by 18.2 bn cubic meters, or hydrogen by 4.2m tonnes in order to process primary iron ore into ore-based metallics (OBM) such as direct reduced iron (DRI).

- Electricity consumption will rise by 45 TWh to power the EAFs; it could rise by another 213 TWh to produce the hydrogen needed to process primary ore.

- EAFs can be virtually carbon-free if fed on zero-carbon electricity. They can cope with the intermittence of renewable energy, but the economics of running for fewer hours on cheaper renewable power vs. continuously on grid power are not always favourable. Running on renewables would also require access to both wind and solar electricity (and possibly some storage) to ensure e.g. 5000 operating hours per year (57%), down from 7600 (87%) with grid electricity.

- Manufacturing OBM using hydrogen requires uninterrupted access to hydrogen sources, although with some volume flexibility. Achieving this through renewable electricity would thus also require some optimisation work.

- Both OBM and hydrogen production require a small amount of uninterrupted grid electricity which cannot be provided by renewables.

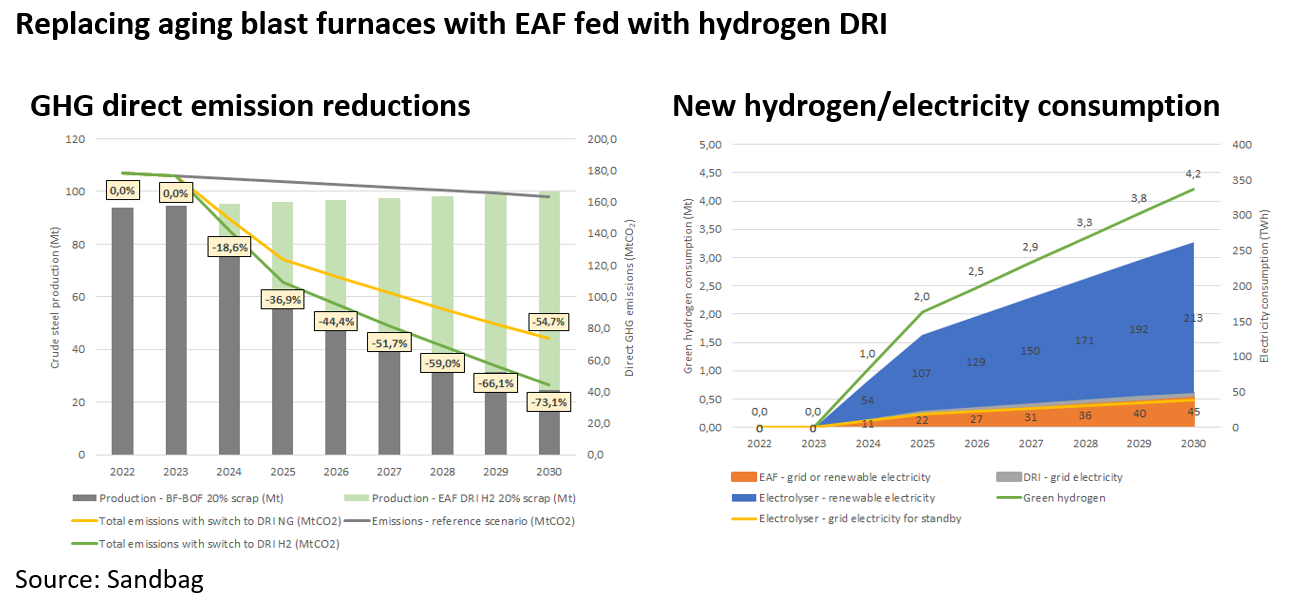

- Emission reductions in 2030 could reach 73% (scrap + DRI from H2), including 41% achieved from optimised scrap use.

- There is a risk that much of Europe’s EAFs will use imported processed ore (DRI) if that product is not covered from a Carbon Border Adjustment Mechanism.

- Alternatively, by optimising the use of European steel scrap, the annual need for fossil gas (or hydrogen) can be reduced by 60%, down to 7.5 bn cubic meters gas (or 1.7m tonnes hydrogen) for the EU + UK. 126 TWh would be saved annually, compared with using only 20% scrap.

- Doing this first would also require less hydrogen storage capacity, and delay the need for green hydrogen by three years.

- Contrary to widespread belief, scrap quality does not make impossible to substitute BF-BOF steel mills with EAFs in the production of high-end steel, provided that scrap management is improved and that scrap impurities are diluted by the addition of some “virgin” iron like DRI.

- Optimising the use of scrap would mainly require better segregation of scrap categories which should happen as EAF steelmaking expands, and better assessment of scrap quality for which the technology is available and inexpensive.

- Additional savings of renewable electricity would be achieved through reuse in the construction sector, or through ‘direct recycling’ which consists of processing end-of-life steel objects without melting them in an EAF.

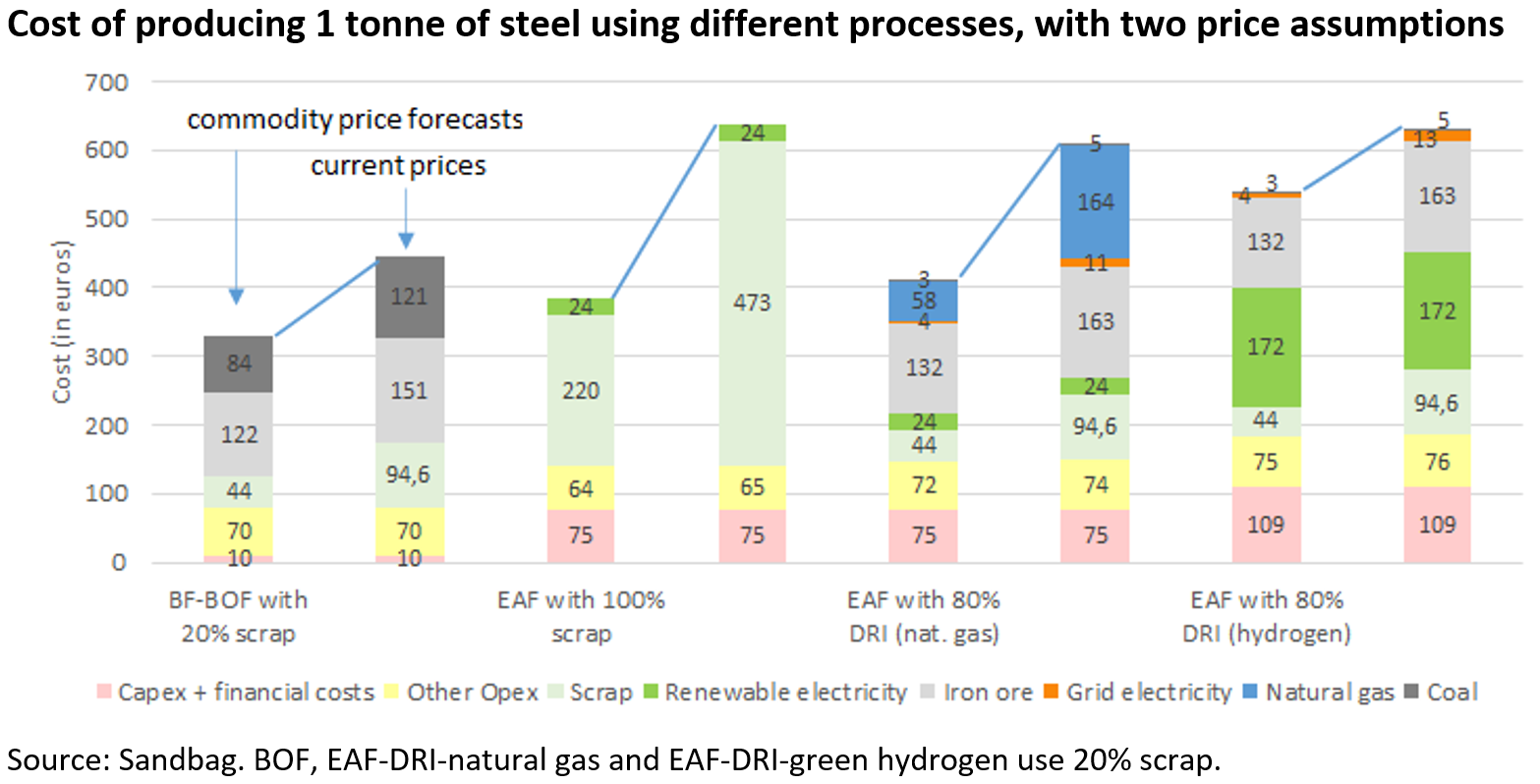

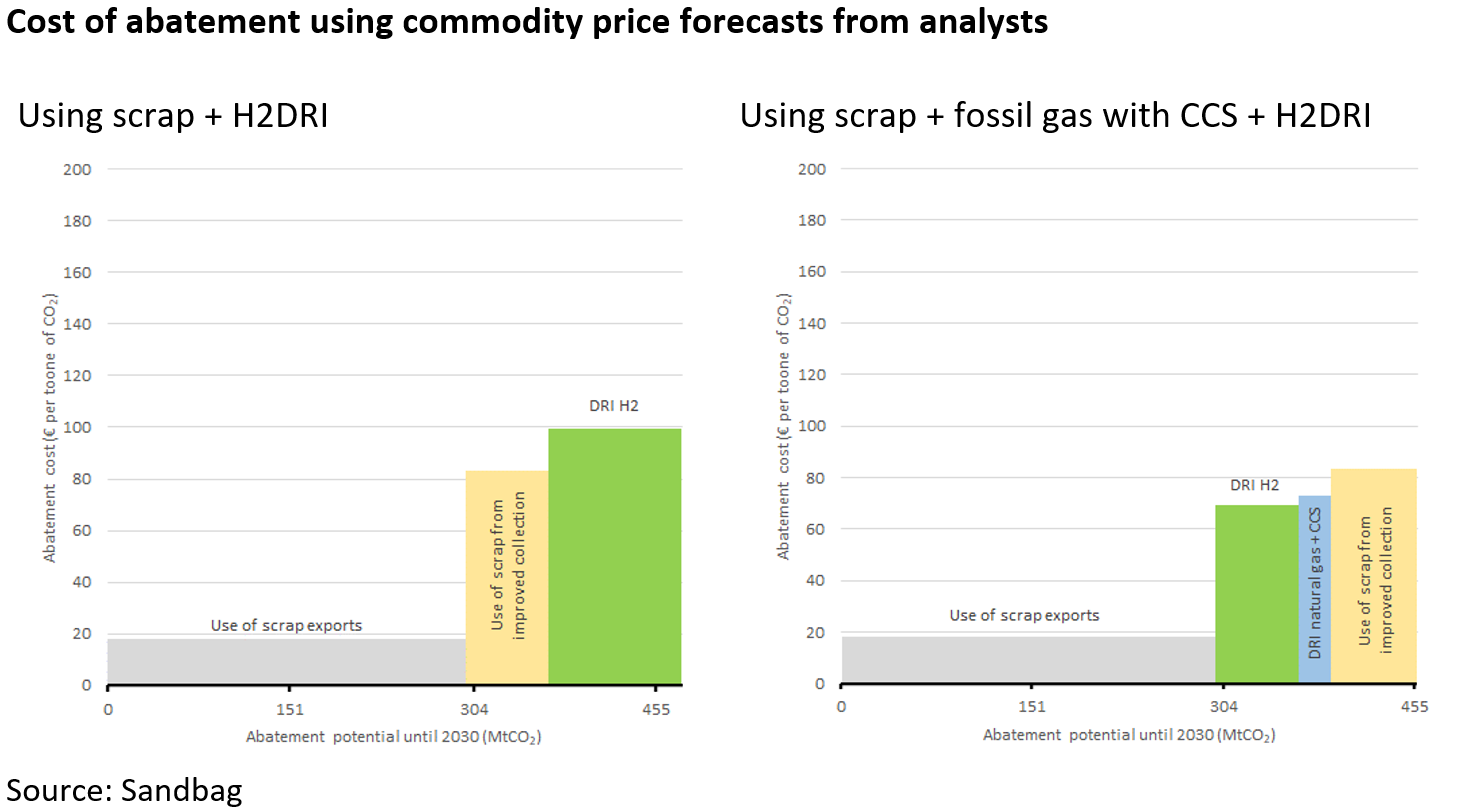

- The difference in production costs of each process, and therefore abatement costs, are closely dependant on commodity prices.

- Although abatement costs are within the range of carbon prices recently seen in the EU ETS, the free allocation of emission permits as protection against carbon leakage largely cancels out the price signal created by that market.

Policy recommendations

- Decisions in product design must be made urgently to ensure the sustainability of scrap recycling. Designing products for easier recycle at end of life and easier removal of contaminants will ensure a better, higher quality scrap supply.

- The free allocation of emission permits under the EU ETS is an obstacle to a rapid transition to circular steel.

- A reform of the ETS benchmarks would not resolve the problem of fair competition between high-carbon and low-carbon solutions.

- Most of the transition could happen within this decade. The replacement of free allowances with a CBAM would ensure total protection to plants selling to the EU market. A CBAM should cover ore-based metallics, as well as finished steel products.

- Adding hydrogen to the scope of the EU ETS (with a corresponding free allocation benchmark) would distort competition between secondary, recycled and hydrogen steel.

- The challenge is not about innovative technology but rather access to zero-carbon electricity and better practices in the scrap market. EU funding such as expected from the Climate Investment Fund (now the Innovation Fund) might be more suitable to address these EU-wide challenges than sponsor individual conversion projects.

- For hydrogen steel to be a low-carbon solution, the hydrogen produced must be zero carbon. This should be reflected in policies such as the Renewable Energy Directive (for its industry target), especially as part of the Delegated Acts on renewable fuels from non-biological origin (RFNBO).

Sandbag seen in the media

- Carbon pulse: EU steel sector can achieve major CO2 cuts with switch to electric

- Carbon pulse: Asian steel set to forge ahead with blast furnaces as EU wobbles over border protection

- Montel News: End of free carbon permits key to greening steel

- Industry Europe: 66% reduction in fossil fuel use if steel scrap is used properly

- SteelGuru: Sandbag report highlights role of steel scrap in decarbonization

- EcoPolitic: Scrap and hydrogen can reduce metallurgical emissions by 73%

- French Institut of International Relations: Notes de l’IFRI (in French only)